Model S3 Slurry Separation Station

In our continuing efforts to provide innovative solutions, we have developed our Model S3 Slurry Separation Station. Designed primarily for use in Precast plants, it can also be used in other plants that have small amounts of daily waste concrete. The system is another simple solution provided by BFK, and works in conjunction with our Model AFD1 Automatic Flocculant Dispenser. Waste cement slurry is collected in a small pond or tank. Many times this is the drain discharge from our Model M6 or R2 Reclaimer, but can be almost any slurry washout source. Our AFD1 continuously picks up and pumps out the slurry to keep it agitated. At the same time, it blows flocculants out into the pond, where the continuous pump agitation mixes the cement particles with the flocculant. The S3 stand includes an air-operated double diaphragm pump, which picks up the flocked cement and pumps them into a poly tank. The heavy flocc particles settle into the cone, with clean water canting up and out via a side port, into a clean water collection tank, where it is used for more incoming concrete washout or pumped back to the reclaimer. When an operator sees that the cone is full of cement, they open a ball valve, allowing the flocked cement particles (and some water) to drop into a suspended dewatering bag. The bag is surrounded by a poly tote, which has fork pockets in the bottom. The flocked cement particles are big enough to be captured by the dewatering bag, however, water passes through and is drained back to the small slurry pond. When the dewatering bag is full of solids, it is removed by lifting up the tote containing the full dewatering bag, and hauled out for further draining and disposal. A 2nd tote and bag are supplied with the system so that the first set can be allowed to sit and drain further while the second set keeps the system running. Simply turn the tote upside-down, wash-out the bag and re-use. Dewatering bags are reusable for approx. 10-20 washouts.CONTACT US:

TOLL-FREE US

888-235-8235

TEL

920-894-1113

FAX

920-894-4991

sales@bfktech.com

CONCRETE RECLAIMER SYSTEMS & SOLUTIONS

BFK TECHNOLOGIES INC.

Model S3 Spec Sheet

DOWNLOAD (click on picture)

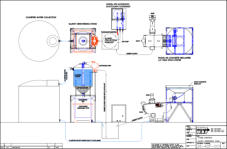

Model S3 System Operational Layout Drawing

BLUE LINE

TOTAL SYSTEMS SOLUTIONS

BFK Technologies Inc.

BFK TECHNOLOGIES INC. 1997-2018

Made in the USA

Proven around the World Since 1997

MANUALS

AND

TECHNICAL

SPECIFICATIONS

ARE

FOR

REFERENCE

ONLY,

OF

CURRENT

DESIGNS

AND

SYSTEMS,

AND

MAY

NOT

REFLECT

THE

DESIGN

OR

REVISION

OF

THE

EQUIPMENT

YOU

PURCHASED,

ESPECIALLY

IF

IT

IS

OF

AN

EARLIER

MODEL.

CONSULT

FACTORY

FOR

EARLIER

REVISIONS.

ALL

DIMENSIONS,

WEIGHTS

AND

TECHNICAL

SPECIFICATIONS

ARE

SUBJECT

TO

CHANGE,

AT

BFK’s

DISCRETION, WITHOUT NOTIFICATION.

WARNING:

Use

of

this

product

can

expose

you

to

chemicals

including

lead,

which

is

known

to

the

State

of

California

to

cause cancer or birth defects or other reproductive harm.

For more information, visit

www.P65Warnings.ca.gov

© Lorem ipsum dolor sit Nulla in mollit pariatur in, est ut dolor eu

eiusmod lorem

Model S3 Slurry Separation

Station

In our continuing efforts to provide innovative solutions, we have developed our Model S3 Slurry Separation Station. Designed primarily for use in Precast plants, it can also be used in other plants that have small amounts of daily waste concrete. The system is another simple solution provided by BFK, and works in conjunction with our Model AFD1 Automatic Flocculant Dispenser. Waste cement slurry is collected in a small pond or tank. Many times this is the drain discharge from our Model M6 or R2 Reclaimer, but can be almost any slurry washout source. Our AFD1 continuously picks up and pumps out the slurry to keep it agitated. At the same time, it blows flocculants out into the pond, where the continuous pump agitation mixes the cement particles with the flocculant. The S3 stand includes an air-operated double diaphragm pump, which picks up the flocked cement and pumps them into a poly tank. The heavy flocc particles settle into the cone, with clean water canting up and out via a side port, into a clean water collection tank, where it is used for more incoming concrete washout or pumped back to the reclaimer. When an operator sees that the cone is full of cement, they open a ball valve, allowing the flocked cement particles (and some water) to drop into a suspended dewatering bag. The bag is surrounded by a poly tote, which has fork pockets in the bottom. The flocked cement particles are big enough to be captured by the dewatering bag, however, water passes through and is drained back to the small slurry pond. When the dewatering bag is full of solids, it is removed by lifting up the tote containing the full dewatering bag, and hauled out for further draining and disposal. A 2nd tote and bag are supplied with the system so that the first set can be allowed to sit and drain further while the second set keeps the system running. Simply turn the tote upside-down, wash-out the bag and re-use. Dewatering bags are reusable for approx. 10-20 washouts.

MyWebsite.com

Settling Pond Designs

Understand this: you can have the best reclaimer design, but with a bad pond system, you won’t be happy. Here at BFK we offer custom settling pond layouts specific to your plant, Free-of-Charge even before you make your purchasing decision. Give us your plant address and we’ll Map it on Google to determine your existing pond set-up. Or email us a basic layout of what you currently have, and we’ll take it from there.Flocculants and Auto Flocc Feeders

We’ve been working with flocculants for more than 15 years, testing different types and learning how to make them work properly in your water system. We offer our own proprietary Automatic Flocculant Dispenser system that will dispense active flocc particles in your settling ponds. This helps to clean up your ponds, and settles fine particles like cement much more quickly than gravity alone. Check it out here, we think you’ll like it.Slurry Dewatering Stand

Precasters, check this one out. This is the system you need to work in your plant where there is no need and no room for a settling pond. We realize you’re not ready-mix - you don’t usually need large, extensive settling ponds. The SDS is designed to collect the slurry from the reclaimer, capture the solids, and return clean water back to the reclaimer. Works well with our Models M6 and R2 Reclaimers.

Slurry Dewatering Stand

Precasters, check this one out. This is the system you need to work in your plant where there is no need and no room for a settling pond. We realize you’re not ready-mix - you don’t usually need large, extensive settling ponds. The SDS is designed to collect the slurry from the reclaimer, capture the solids, and return clean water back to the reclaimer. Works well with our Models M6 and R2 Reclaimers.pH Control

The pH level of your water CAN be lowered. Using CO 2 to lower pH is a proven technique, and BFK is now pleased to offer the industry leader in pH Controls, the CO 2 Washout & Stormwater Treatment System from ATSI. ATSI has been in the pH game for over 20 years. It’s a perfect compliment to your Reclamation system.Filter Press

We don’t build ‘em, we rarely even sell ‘em. But if you’re looking for one, we can hook you up with a press company that cuts no corners. We’ve heard all the sale pitches about automatic operation, no operator needed, pitch after pitch after pitch. “Plug ‘em in and walk away”. Yeah right. Like BFK, they’ll lay it out for you, what to expect and what not to expect. No more, no less.